Application of visual light source in new energy industry

Application of visual light source in new energy industry

In these few years, with the implementation of “carbon peak” and “carbon neutrality”, the new energy industry has been rapidly developed by policy support, especially the photovoltaic and lithium battery markets. At present, Chinese lithium batteries are continuously optimized in the direction of high energy density, long endurance and high safety. While maintaining rapid development, the consistency, yield and safety of lithium electric products have attracted much attention.

LOTS not only focuses on the development of new energy industry, but also be business partner with a number of new energy leading enterprise equipment providers to provide core solutions for new energy production technology.

In the whole production process of lithium electricity, visual inspection is mainly used in the following links:

※Inspection electrode material roll film

※Bad welding inspection

※Package inspection

※Product appearance inspection

Inspection electrode material roll film

In the rolling film material, it is easy to produce poor film coating, scratches, cracks, extra material of roll film, less material, impurities and other problems. If these defects flow into the next link, there will be fatal harm after packaging and forming, so surface defect inspection is particularly important in the production of lithium electricity。

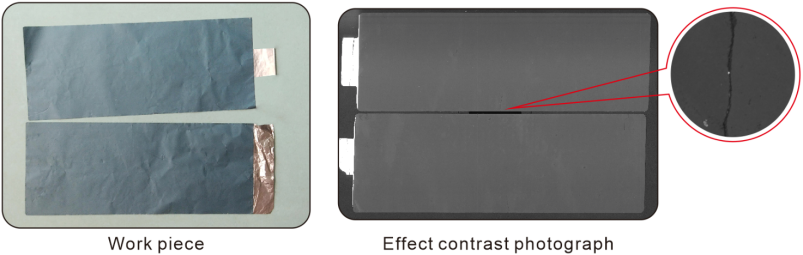

Case:Inspection of surface defects of lithium battery cell film

Before the film cut, most of the area is large and requiring a wide field of vision and fast inspection speed. In visual inspection, we will preferentially recommend the line scan program. The line scan camera can carry out continuous image acquisition, also has the advantages of fast detection speed and large detection area. For the application needs of lithium battery inspection, LOTS has developed 4 generations of line light sources, which have the characteristics of high brightness, good uniformity, good shock resistance and strong sealing.

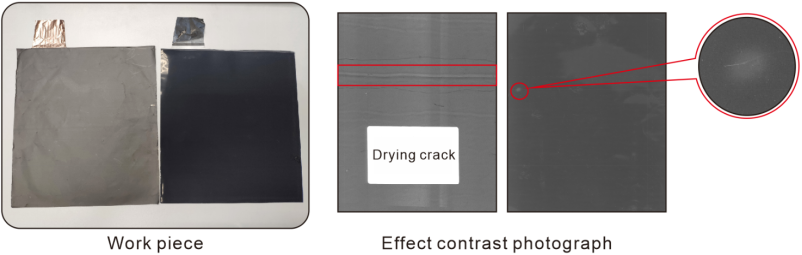

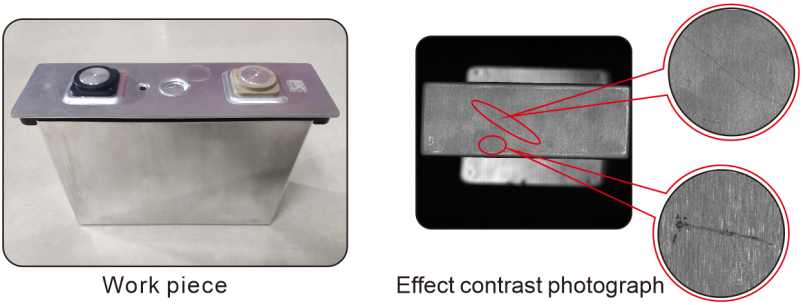

Bad welding inspection

The production process of lithium electric products has a variety of positions of welding, edge sealing, in order to ensure the safety of sealing, often use welding process to fill the seal gap. Welding inspection is the key quality control of lithium electricity production. The common defects in the welding process include burst point, leakage welding, welding penetration, etc.

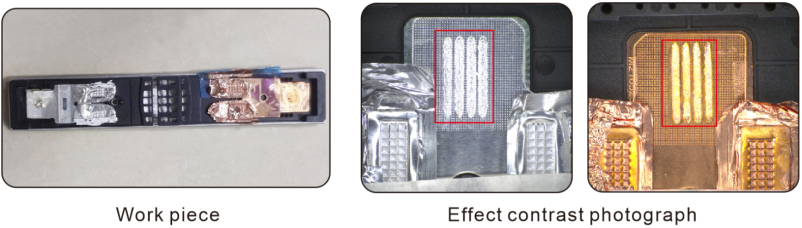

Case:Welding outline detection of lithium battery

Conventional lithium battery welding inspection, mostly using 2D imaging analysis, we can use our combined light source for inspection.

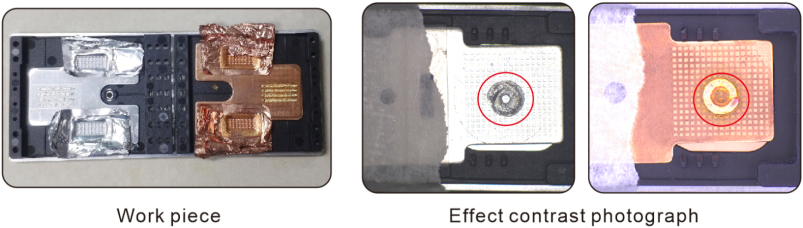

Package inspection

Because of the use of glue in the packaging of lithium electricity, so the detection of glue contour is also an essential link in the production of lithium electricity.。

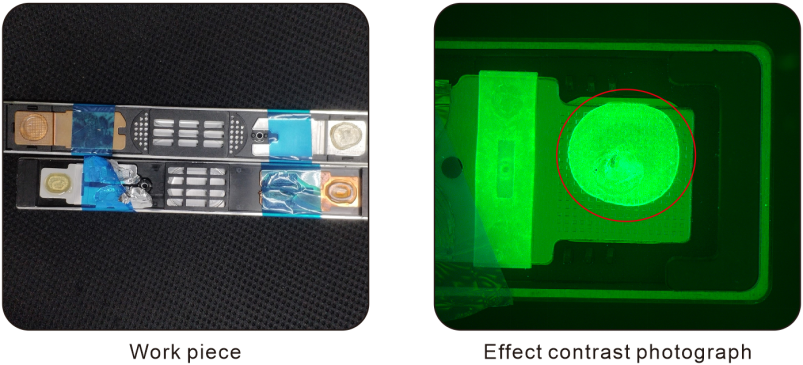

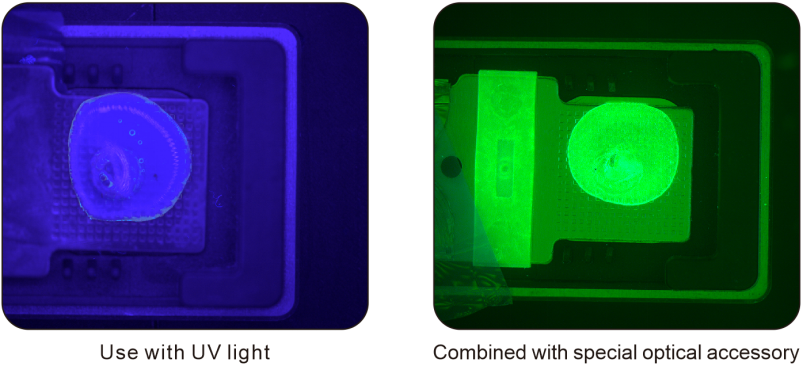

Case:Lithium electrode position glue profile inspection

Glue inspection also uses 2D array imaging, but the glue surface is transparent, colorless and smooth, the use of conventional light source scheme does not necessarily have good results; At this point, we can use UV light to make the glue outline stand out.

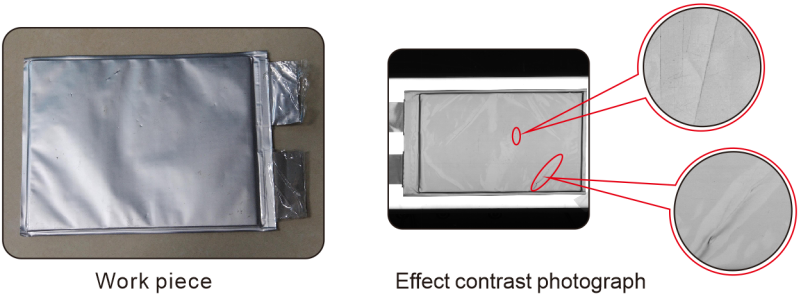

Product appearance inspection

Lithium-ion batteries are packaged into a battery pack, and their appearance is strictly monitored. In production, the packaging is mainly operated by the machine. Most of the common problems such as scratching, crushing and dirt are caused by the machine in production.

Case:Lithium battery outline and surface dirt scratches

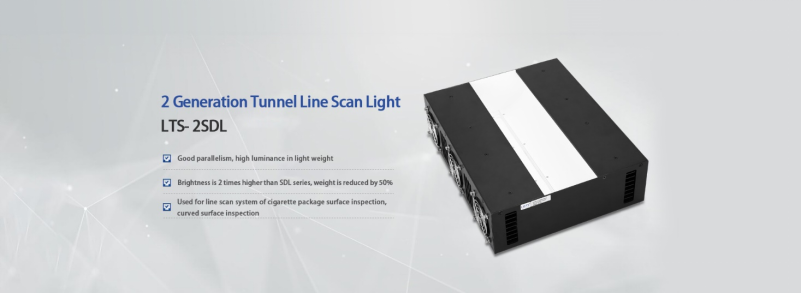

The finished automobile power lithium battery has a large area, so it is recommended to use line sweep vision scheme. In order to meet the requirements of non-directional scratches and creases detection on smooth surfaces, uniform light source is usually used for irradiation and line scan camera imaging. Tunnel line light source combined with coaxial light source is often used in lighting to make the defects prominent and easy to image analysis。

LOTS has many years of experience in the lithium battery testing industry, helping lithium manufacturers to improve productivity, product quality and reduce production costs. In the field of new energy inspection, our company has the cutting-edge lighting technology, the latest and most complete application program, welcome customers and friends to come to consult and understand.

Ms.Cici

Ms.Cici

8618319014500

8618319014500