Li-battery industry

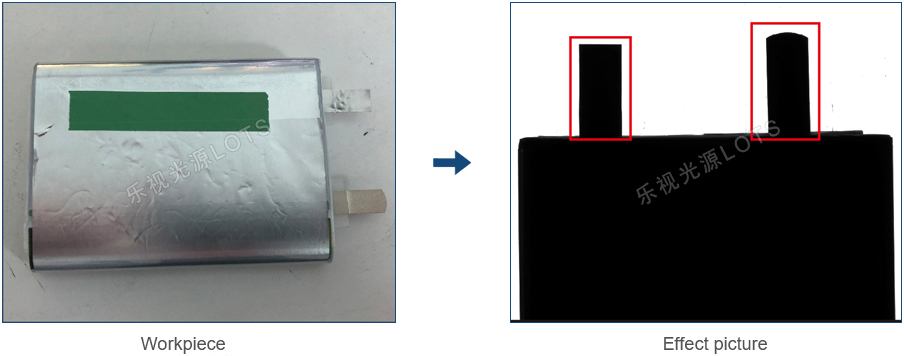

Lithium battery pole ear inspection

Light model: LTS-2FT100100-W

Opaque material, using backlight from the bottom, the background is white and pole ear of battery is black, the outline is obvious contrast.

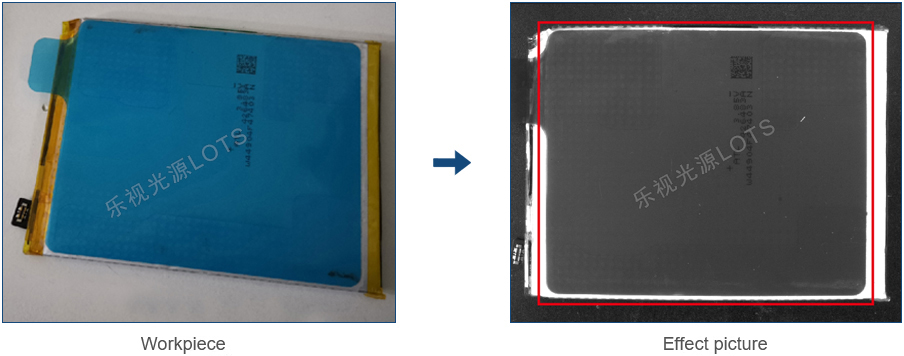

Film of battery inspection

Light model: LTS-2BRS15030-W

Film is opaque material, battery surface is strong reflection, use Bar Light luminate by side, battery surface is black and film is white.

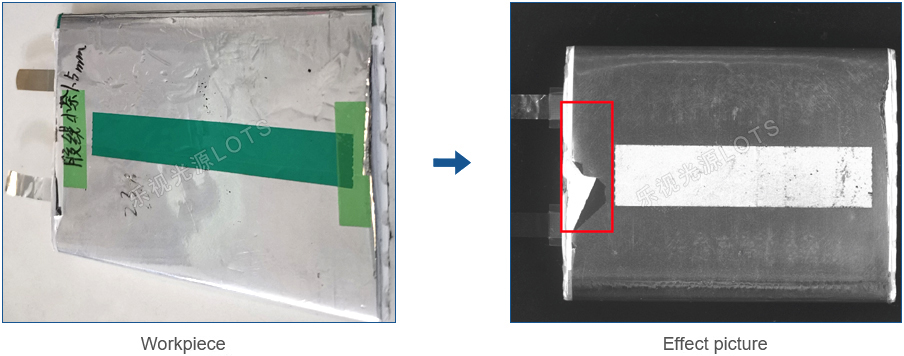

Battery surface packaging defects inspection

Light model: LTS-RN17315-B

The unpacked part of battery is white, used the Low Angle Ring Light blacken the package. The damaged part of package is white, high contrast with the package.

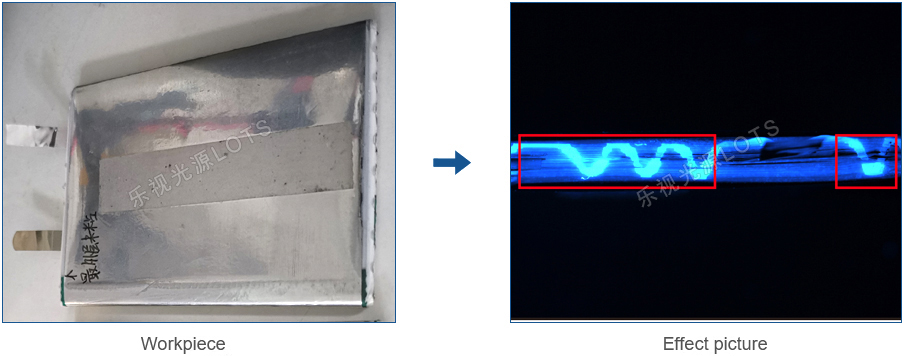

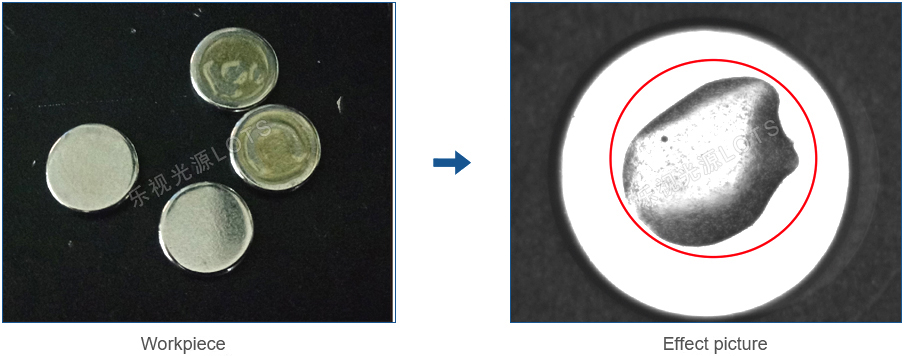

Battery glue inspection

Light model: LTS-15060-UV385

Use UV-Ring Light, according to UV light has a short wavelength and strong reflection, but the glue cannot penetrate but will have highly reflective from surface. add a filter to improve the contrast.

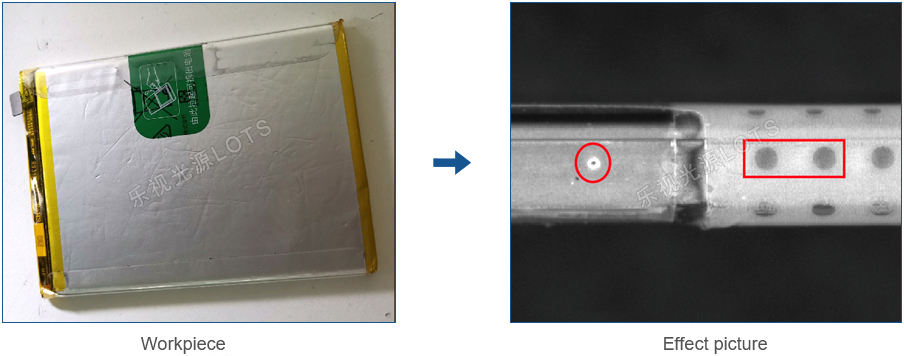

Position of glue on the battery inspection

Light model: LTS-COX40-B

Used coaxial light to luminate the surface vertically and uniform. After using glue on the bottom, the reflection between glue and the surface is different, position of glue high contrast with the surface.

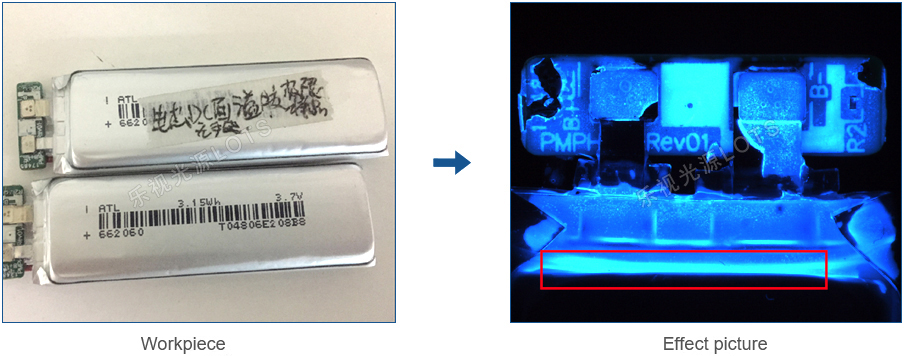

Surface of PCB battery glue inspection

Light model: LTS-RN9030-UV385

Use UV-Low Angle Ring Light, Low Angle Ring Light makes the underside metal less reflective, high contrast the glue with the background.

Battery side defect inspection

Light model: LTS-2BR7530-W

Side to side luminated by two Bar Light, background is black and the side surface is white. low working distance to reduce the reflection of the battery surface, also luminate the small hole.

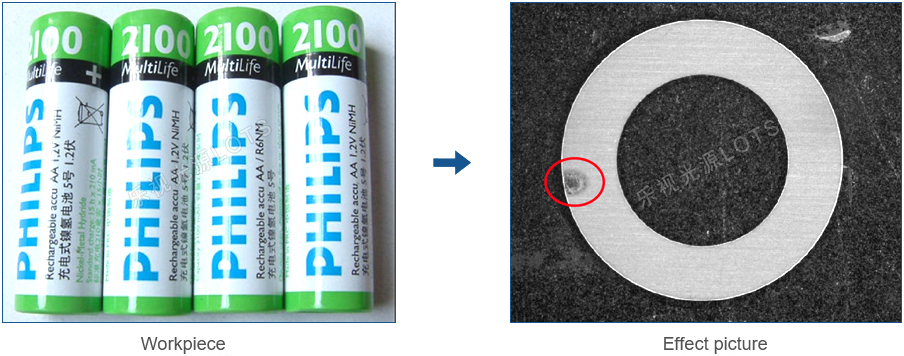

Battery bottom protection plate detection

Light model: LTS-RN5060-B

The protection plate is dirty and damaged, the metal material is strong reflective, high angle ring light luminate the protection plate be whiten, the damage is black, so contrast is obvious.

Ms.Cici

Ms.Cici

8618319014500

8618319014500