Metal industry

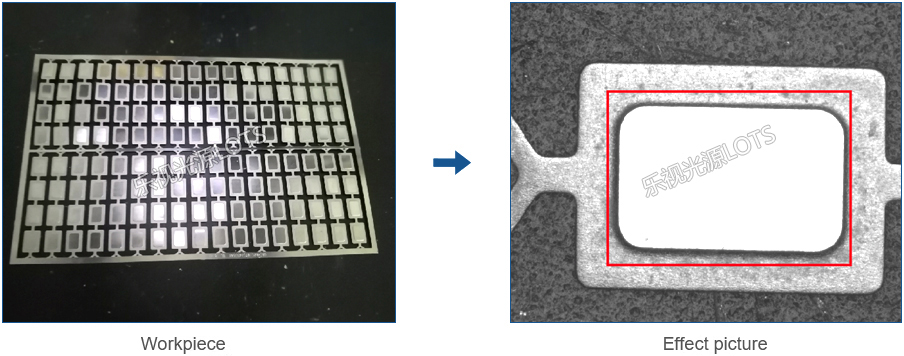

Metal sheet positioning inspection

Light model: LTS-3CON50-W

The feature to be inspection is edge positioning, the metal sheet is strong reflective material. select narrow angle coaxial light with better parallelism is used to luminate the metal sheet as whiten and the edge as blacken.

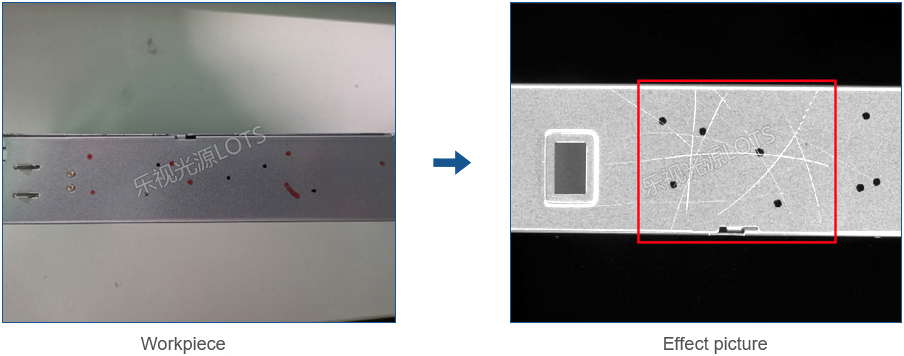

Metal box surface defect inspection

Light model: LTS-2BR15030-B

Metal box is strong reflective, so we use Bar light to illumination on both sides. When luminate the metal, it reflects off the rest of the metal as blacken and scratches as whiten. contrast is obviously.

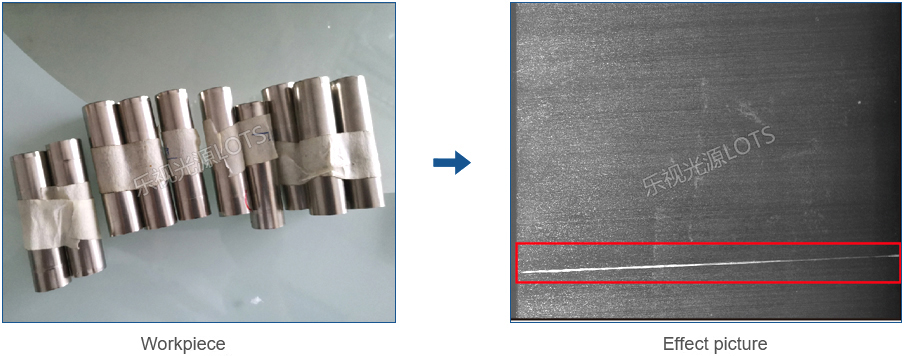

Metal cylinder surface defect inspection

Light model: LTS-2COXL230-W

Test shooting was used with a rotating platform of a line-scan camera. Coaxial light makes the surface of the product get illuminate uniform, the metal cu-liner defects were painted whiten and the background was blacken.

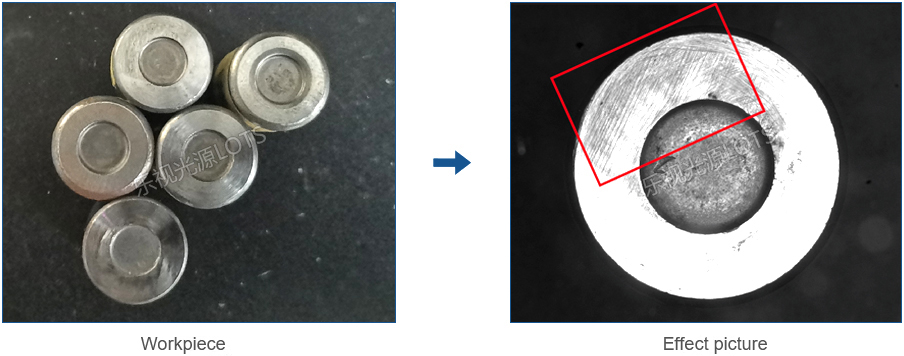

The head of metal cylinder inspection

Light model: LTS-COX40-W

Using coaxial light to illumination the head of metal cylinder, smooth part on the head is whiten, the rough part is low reflective, also the rest part of the picture get lower gray level is blacken, reach the inspection purpose.

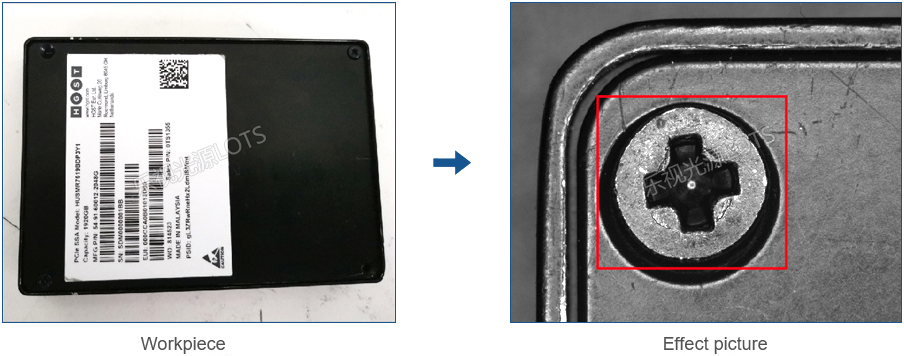

Screw hole positioning inspection

Light model: LTS-RNH5060-W

Select the 60 degree Ring Light illumination, can luminate the background and screws, at the same time screw and round hole gap gray level is low, so that the screw edge is clear, the contrast is obvious.

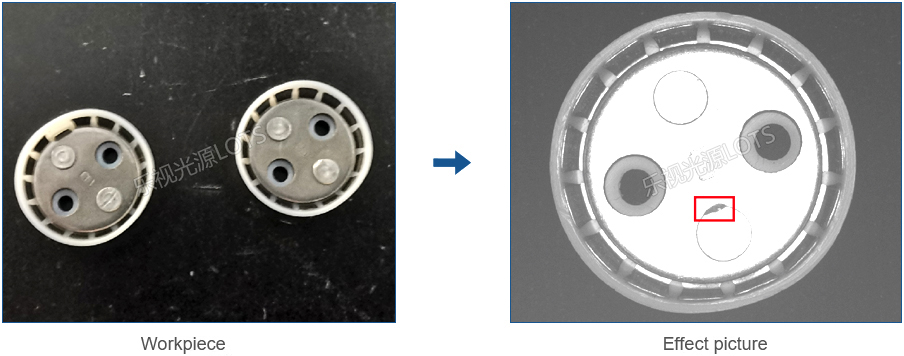

Inspection metal part under the button

Light model: LTS-COX60-W

Need to inspect the metal part defect, so select coaxial light to vertical illumination the object, the big gap is black and the surface is white, contrast is obviously.

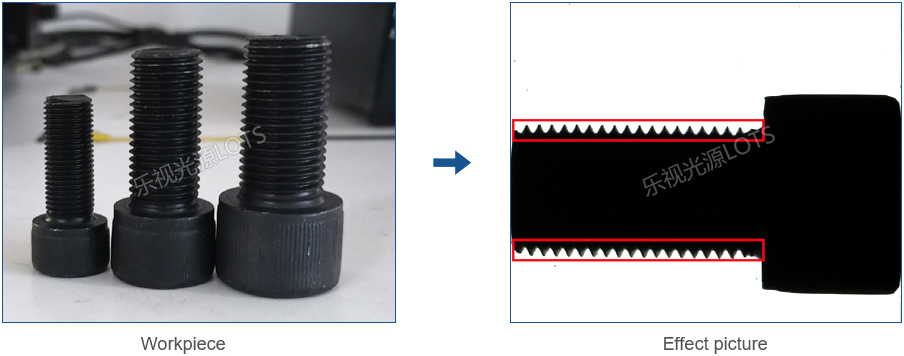

Screw threads inspection

Light model: LTS-2PFT7070-W

Using collimated back light to make the edge sharper, reduce the edge of screw threads blur, it could improve the accuracy for inspection, the contrast is obviously.

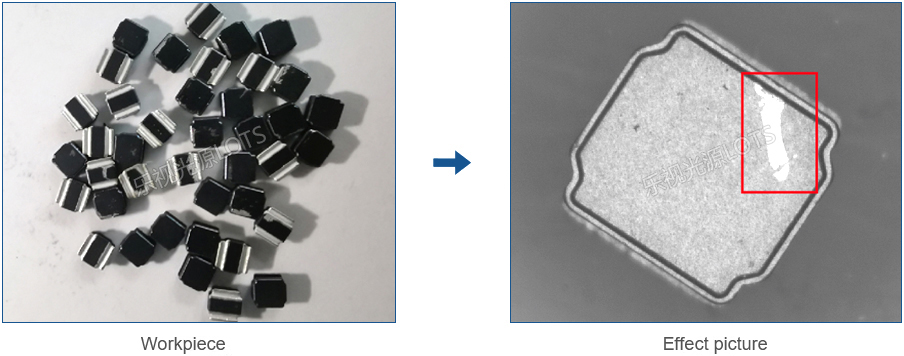

Small component defect inspection

Light model: LTS-COX40-W

Inspection silver plating, the defect part has strong reflective, select coaxial light is used for vertical illumination. The gray level of silver-plating defect is higher than the background, contrast is obviously.

Ms.Cici

Ms.Cici

8618319014500

8618319014500