Application case of machine vision light in automotive industry

With the rapid development of machine vision, image processing, intelligent positioning and defect detection are widely used in modern automobile industry. Especially in the automobile manufacturing industry, machine vision is indispensable to the production and detection of small auto parts and the identification of large auto autonomous driving AI. Here we share some common test cases to understand the application of visual light sources in the automotive industry.

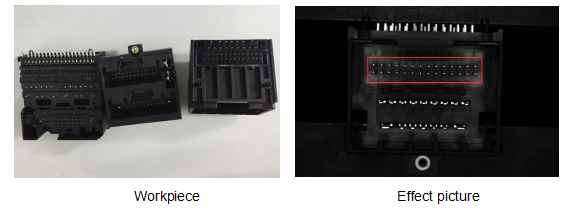

■Automotive connector pin detection

Lighting model:LTS-3RN12090-R

Detection of the car connector pin, the use of high angle ring light vertical irradiation, so that the outline of the tip part of the needle is obvious, is conducive to the grasp and alignment of the manipulator

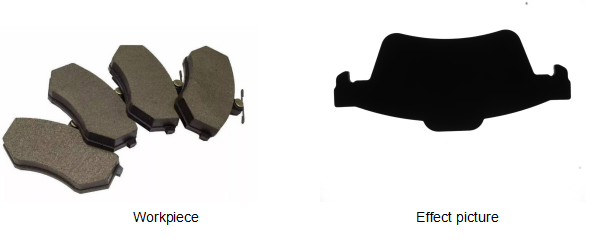

- Auto brake pad contour detection

Lighting model:LTS-3FT250250-W

Detect the contour of the brake pad, determine whether the material is correct, and whether it is consistent with the assembly direction. At the same time, accurate positioning is needed. The backlight can be used to clearly present the contour.

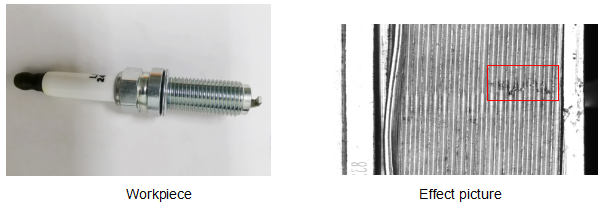

- Automotive spark plug thread defect detection

Lighting model:LTS-2SDL260-W

The spark plug screw defects are detected. The spark plug is cylindrical, and the line scan camera can be used to spread the screw well. The tunnel line scan light source can make the whole screw shine evenly and the defects become prominent.

![]()

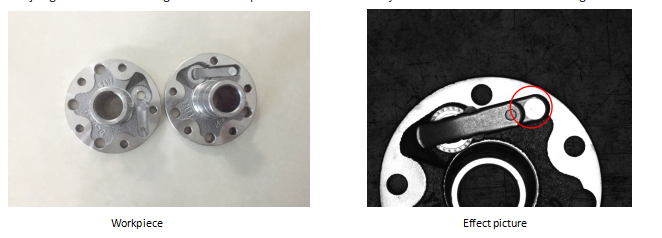

- Automotive assembly rivets testing

Lighting model:LTS-4FTR300200-W

As this part is large, the position of the rivet should be detected in the whole field of view to avoid misjudgment. The back light is used to present the rivet clearly and the contour contrast is high

![]()

- Automobile assembly gasket detection

Lighting model:LTS-4BR25030-W

Need to detect the presence or absence of gaskets and locate the direction of gaskets. Bar light source with high-cost performance can be used, which not only meets the requirements of detection, but also has strong advantages in architecture

![]()

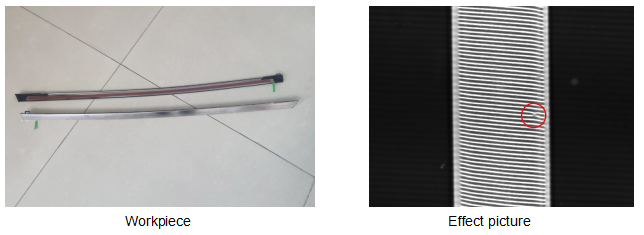

- Automobile reflective strip bad detection

Lighting model:LTS-LFM100-W

Automotive reflective strips are widely used in automobiles, but this kind of highly reflective material is also a difficulty in defect detection. The use of flat dome light source with grid can well highlight the defects, and the defects can be judged by the deformation position of the lines.

![]()

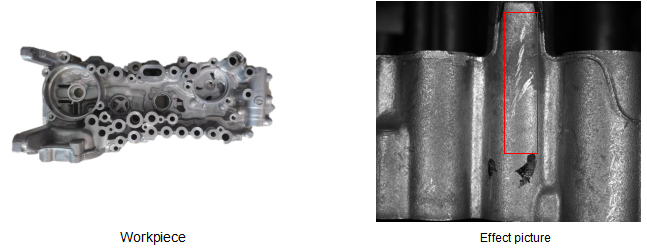

- Transmission casting parts surface defect detection

Lighting model:LTS-2HPR180-W

The surface of the cast is frosted, where the defect is smooth, and the sand hole will appear black. Because the casting parts are large, it is difficult to do a full inspection, which requires the manipulator to move the light source and camera for multiple detection, and the use of ring shadowless light source can well highlight the defects.

![]()

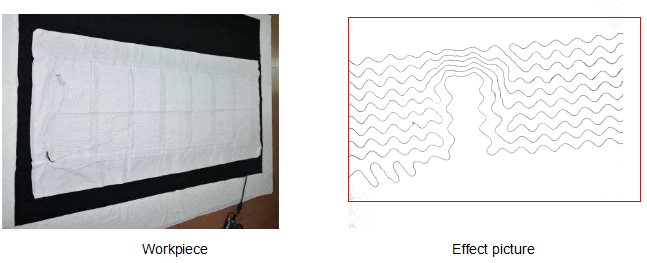

- Steering wheel heating circuit detection

Lighting model:LTS-4FT200200-IR850

The steering wheel is covered with a fiber layer, and the heating wire is located in the middle of the fiber layer. The front light cannot be detected, and the infrared back light is used to penetrate the fiber layer, so that the line is clearly presented.

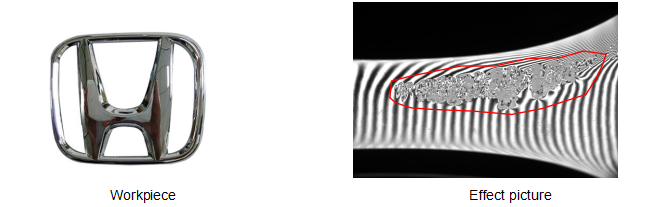

- Detection of surface defects of automobile emblem

Lighting model:LTS-LFM100-W

Most of the car logos are chrome reflective products, the surface is very smooth, and the shape is irregular, the use of flat dome light source with grid can well highlight the defects, highlights the defect characteristics by the deformation of the grid.

And that's all for today, Thanks for your support. I'll see you next time

Ms.Cici

Ms.Cici

8618319014500

8618319014500