5 Essential Libraries for Computer Vision Projects - computer vision libraries

Cut is performed without any listenable alteration during premastering. Transcription will be done "as is" which can results in problematic cuts especially near the center of the record. Overall volume might be lower due to absence of other controlling parameters. Please make sure that you follow Vinyl master guidelines . Studio might refuse to cut, in which case you will receive a report on what should be changed to proceed.

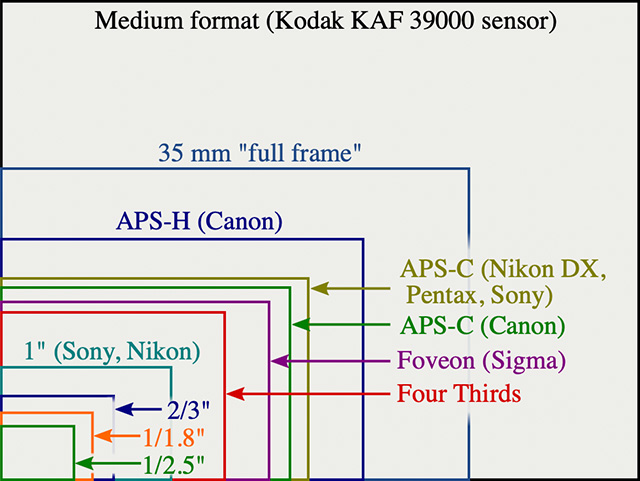

We want to help reduce the confusion and make it easier for prospective customers to understand what they're buying. Alongside DPReview, PetaPixel, Cameralabs, Gerald Undone, The Art of Photography and potentially more publications and YouTube channels, we will adopt a new naming system that better conveys the physical sensor size of what are often referred to as 1-inch type sensors. The physical size of an image sensor has a real, sometimes significant, effect on image quality. We want readers to better understand the sensor size of a product without needing to get into the weeds on the history of CRT broadcast cameras and hypothetical glass tubes.

2018410 — Noterai difficoltà a mettere a fuoco un oggetto posto a distanza ravvicinata. Alcuni gesti molto comuni quando si legge sono quelli di ...

The DMM process was developed and issued in 1982 by a collaboration between two German companies Teldec and Georg Neumann GmbH.

Interesting trivia: two DMM cutting lathes have been obtained by Church of Scientology, which supposedly uses them to record the speeches of their founder L.R.Hubbard and which are placed into "time-capsules" together with spring loaded phonographs. The idea behind that is if someone digs out and opens such capsule after a predicted apocalypse, they should be able to listen to Mr. Hubbard speeches without the use of electricity.

Moving forward, we will refer to typical 1-inch type sensors as Type 1 (12.7 x 9.5mm). For even smaller image sensors, we'll refer to those in a similar format, writing out Type 1/X (approximate sensor dimensions). While we could refer to larger image sensors similarly – full-frame cameras would be Type 2.7, for example – there's no need, as those sensor formats are well-understood and sensible. Nothing is misleading about "full frame." There is possible confusion with medium-format cameras since medium-format sensors come in a couple of sizes (44 x 33mm and 53.4 x 40mm), but we always make a point to note sensor size when reviewing medium-format cameras, like the Fujifilm GFX 100S (44 x 33mm) and Phase One IQ4 150MP (53.4 x 40mm).

Many product data sheets for UV light curing adhesives and materials suggest that they need to be cured with 365nm UV light, or they show an example cure ...

Those are some very good salaries for a regular software engineer. Unless she's an extraordinary candidate (and with B1 German and a generic ...

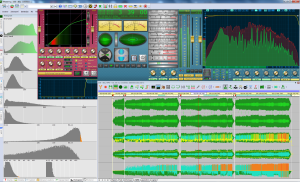

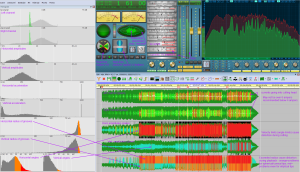

Mastering machinesoftware

VVM (Vinyl Visual Mastering) is software tool designed specifically for needs of a vinyl mastering engineer (ME). It includes a state-of-art computer simulation of the mastering process that allows setting up cutting parameters and simulating the cutting process before the actual cutting is performed.

DMM and Lacquer cuts each have their own fans and supporters. Please note that neither technology is in no way a replacement for a proper mastering and recording process and all pros/cons of each technology can only account for the transcription onto a vinyl record as a physical medium.

Is it an outright lie when manufacturers make claims like "our smartphone is the first to include a 1-inch sensor," or "our drone uses a large 1-inch image sensor?" Not exactly, but at the very least, it's misleading and confusing. For this reason, Sony Semiconductor, one of the world's premiere sensor makers, has already changed its naming system.

(*) - be aware that many factories or studios refer to the "flat cut" as a best sounding cut with minimal alterations, which is mostly equivalent to our "1. STANDARD CUT".

Mastering machineonline

The odd naming convention goes back to the dimensions of a hypothetical glass tube that could surround the 1-inch sensor. Live broadcasting cameras in the 1950s used cathode-ray tubes (CRT) to project an image line after line. The glass tube that surrounded a signal plate had a 1-inch diameter, although the photosensitive area of the tube was only about 0.63" in diameter – or around 16mm. The typical diagonal of a modern 1-inch type sensor is, you guessed it, 16mm (15.9mm, to be precise).

Horizontal amplitude is a movement of the tip of the stylus from left-to-right in the groove‘s path. Vertical amplitude is a movement up and down - deeper into the groove and back up. Horizontal amplitude carries most of the transcribed audio signal, vertical amplitude carries the difference between the left and right channel.

R Gulve · 4 — Abstract—A dual-tap coded-exposure-pixel (CEP) image sen- sor is presented and validated in two computational imaging applications.

VOTAN 056 - ,,,,,,,,,H,.

Mastering machinepython

An advanced AI platform that revolutionizes customer support & sales through autonomous, phone-based agents. Powered by $RING token.

In any case, if you are unsure, please add test pressings to your order to make sure you are okay with the sound before moving on to the main pressing.

The Scattering of Light by Reflection or transmission. Diffuse reflection results when light strikes an irregular surface, such as a frosted Window or the ...

A 1"-type sensor must be an inch, right? It would make sense. However, as surely some of you know, a 1-inch sensor is considerably smaller than an inch. It's confusing and odd. If the name of a sensor includes a unit of measurement, why is the measurement not accurate? To overcome this confusion, we will change our naming system style guide to "Type 1 (sensor dimensions)." This will make it immediately clear what the actual sensor area is when discussing the smaller "1-inch type" image sensors found in many smartphones, drones, and compact cameras.

Mastering machineexamples

After all this time, and despite using wildly different technology than CRT broadcasting cameras in the 1950s, the 1-inch nomenclature has remained. The photosensitive area in question wasn't an inch in diameter back then, and it still isn't now. Modern 1-inch sensors refer to a hypothetical CRT tube that would be an inch in diameter to theoretically fit around a 1-inch type image sensor.

Same as "LOUD CUT", but with wider groove that helps stability of the playing stylus (useful for playback in loud environments that produce a lot of vibrations). Wider groove results in higher surface noise and reduced available playtime. Visual separating grooves in-between tracks are done more prominent.

201939 — 2017 Volt Service Rear Vision System · 1) The Gen 2 (or at least my 2017 Volt) does not supply power to the rear vision camera through BCM6 ( ...

Diverse applicazioni di visione artificiale richiedono l'ispezione completa di un oggetto, individuando dettagli posizionati sui lati piuttosto che sulla ...

Minimizing risk of distortion on most turntables, only necessary edits are performed on the audio to achieve best possible sounding record.

All in onemasteringhardware

Please note that higher volume and bigger vertical amplitudes also involve a higher risk of distortion and mistracking on some turntables.

Do you want to visit us at Prague and be present during your cutting? Do you only want to use de-esser, but otherwise go with the "flat cut"? Do you want to achieve super-loudness similar to a record you own and are able to send us?

Our database will be updated to reflect this change later down the road, but we will employ the new naming system from today.

All of these options and more are available, keep in mind that they will be billed on an hourly rate of a mastering engineer.

While compact cameras with small sensors are becoming rarer, there are still many popular cameras with Type 1 image sensors, like the Sony RX100 Mark VII. Where we most often see small sensors are with new smartphones and drones. We hope the change to "Type 1 (sensor dimensions) sensor" will make it easier to understand the sensor size for these new products and help readers make more informed decisions about what they'd like to purchase. While there's no doubt that you can capture amazing images with small image sensors, sensor size does matter.

Masteringstudio equipment list

Same as "DJ LOUD CUT" but with even wider groove, resulting in maximum stability of the playing stylus. Even further reduction of available playtime.

DMM (Direct Metal Mastering) is one of the two existing technologies to create original (master) discs needed for vinyl record pressing. The other, older technology is cutting into a lacquer disc. The majority of our vinyl production is done using DMM, but lacquer cutting or processing of a supplied lacquer is available on request.

Cut with an emphasis to minimizing risk of distortion on all types of playing styluses and cartridges. Might result in very quiet records with less distortion but higher surface noise.

Masteringhardware chain

Even with the resurgence of vinyl records, no one has been able to manufacture a brand new DMM cutting lathe since their original batch produced in the 80's – 90's.

Supplied lacquers should be sent for processing as soon as possible so the grooves cut into the soft nitrocellulose surface do not degrade due to heat and environmental conditions, typically resulting in a loss of high frequencies (unless the cutting lathe is right next to a galvanic processing room, in which case lacquers need to rest for several hours until they stop evaporating toxic gases after the cutting process, which would pose a health risk and could create "bubbles" due to evaporation under the immediately silvered layer).

Custom selfie lights are ideal for remote works and influencers. Custom logo selfie ring lights for businesses can provide professional lighting for ...

There are around 12 DMM cutting lathes operating in the whole world that produce masters for manufacturing vinyl records.

DMM transcribes audio coming from a workstation or a master tape into a copper plate using a diamond cutting stylus (the copper that is being cut into is a plated layer on a non-magnetic steel substrate). This creates an original "positive" (master/mother) disc that is used to create a "negative" stamper in an electroforming galvanic process. Stamper is then attached onto a pressing machine and is used for a mass replication – pressing of vinyl records.

Mastering machinepdf

Neumann was exclusively supplying the technology and mastering systems until the late 90's when the company left the music industry during the decline in popularity of vinyl records.

Thicker layer of lacquer allows for higher vertical amplitude and a different shape of cutting stylus allows cutting of bigger angles in the horizontal amplitude, it however carries a risk that the softer nitrocelulose layer (compared to DMM‘s copper layer) will „print-through“ the groove that is currently being cut and will deform neighbouring previously cut groove (pre-echo) or will deform the surface that will be cut into on the next revolution of the disc (post-echo, which is much less common).

In comparsion with lacquer cutting, lacquer is cut into a nitrocellulose layer coated on an aluminium disc using a heated sapphire cutting stylus. Because nitrocellulose is not electrically conductive it needs to be sprayed with a thin layer of silver in order to be usable in a later electroforming galvanic process. We use traditional lacquer processing which includes three copies: "negative" (father), "positive" (mother), "negative" (stamper). Lacquer itself is consumed and discarded in the process.

If you are mainly familiar with lacquer cuts and would achieve similar level of loudness with DMM, please specify that you would like to order a LOUD CUT during your order processing (please note that this is directly related to a possibility of higher distortion level in loudest parts of the recording). If you have a studio or a mastering engineer that supplies you with lacquer cuts you like, please state that you would like to use a supplied lacquer during your order.

Consider a CAD system that is aiding an architect and is able to identify critical parts of the construction and address them specifically. That is what VVM achieves for a mastering engineer.

Overall volume and loudness of the record will be comparable to most typical lacquer cuts, with higher risk of distortion in critical parts of the recording (loudest parts of the audio and near the center of the record). Reduced available playtime.

If you want to avoid specific edits in premastering or cutting, please see "ASSISTED CUT / REFERENCE / SPECIAL REQUEST" instead.

It's confusing. The image sensor "format" is not the same as its size. That inconsistency by itself isn't confusing – medium-format doesn't refer to the image sensor size – but it is confusing when the sensor format relies upon an inaccurate unit of measurement in its name. If you didn't know the origin of the term "1-inch type sensor," you'd reasonably conclude that a 1-inch-type sensor is an inch wide or an inch in diagonal.

Ms.Cici

Ms.Cici

8618319014500

8618319014500